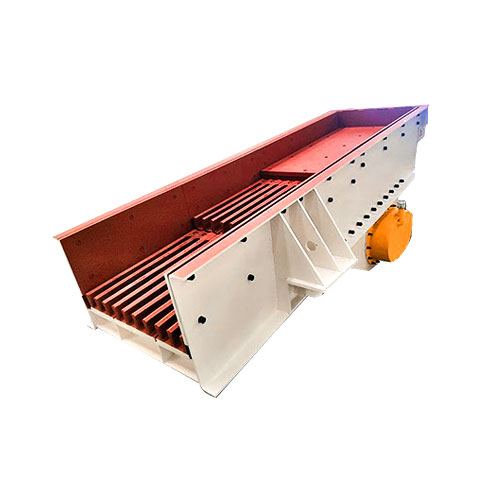

Y Series Vibrating Screen

Y series vibrating screen is vibrated by the circling motion, it’s high efficient screen for filter materials into multiple grade according to the gravel size. For the compact structure and the convenient installation, it is the ideal screening device for prefilter of the feed materials before the primary crushing in the quarry site, it also can be used as separation and filtration solely.

Vibrating screen adopts cylinder type eccentric shaft vibrator and partial block to adjust the amplitude. The materiel sieve drip line is long and more sieving specifications. The circular vibrating screen can also be used for production classifying in quarry, mine, construction, electricity, chemical industry, etc.

Working principle

Y series vibrating screen is mainly composed of screen box, screen mesh, vibrator, damping spring device, bottom frame and so on. The side plate of vibrating screen is made of high quality steel plate.It is connected with the beam and bottom seat of the vibration exciter with high strength bolts or ring slot rivets, and cylinder type eccentric shaft exciter and eccentric block are used to adjust the amplitude.

Vibrator is installed on the screen box side plate to drive vibrator eccentric block produce high-speed rotation through v-belt by the motor so that could produce large centrifugal force to stimulate the screen box produce a certain amplitude of circular movement.The material on the screen is subjected to the impulse passed by the screen box on the titled screen surface and produces continuous throwing motion.So particles that are smaller than the screen hole pass through the screen so as to achieve classification when material enters the screen surface.

Features & Benefits

1. High Processing Capacity: Circular vibratory screens have a high processing capacity, making them ideal for large-scale screening operations. They can handle materials of different sizes and densities, and can quickly separate them based on their size and shape.

2. Easy Operation: Circular vibratory screens are easy to operate and maintain. The inclination angle is adjustable and can be adjusted according to different materials.

3. Low Noise: Circular vibratory screens produce low noise levels, rubber buffer pads are added to the support feet of the vibrating screen base, and there are rubber sealing strips at the connection of the screen frame, which can effectively absorb sound and reduce operating noise.

4. Customizable: Circular vibratory screens can be customized to meet specific application requirements. Screen sizes, hole diameters, and material handling capacities can all be adjusted to suit different needs.

5. Long lifespan: Circular vibratory screens have a long lifespan, with some models lasting for over a decade without significant maintenance requirements. They are durable and reliable, making them a cost-effective solution for screening operations.

| Model | Feeding Size (mm) | Capacity (t/h) | Screen Panel (mm) | Screen Area (m²) | Power (kw) | Overall Size (mm) |

| 2YK1548 | 0-200 | 0-160 | 1500*4800 | 7.2 | 11 | 5000*2900*2900 |

| 3YK1548 | 0-200 | 0-160 | 1500*4800 | 7.2 | 15 | 5000*2900*3400 |

| 2YK1860 | 0-200 | 0-200 | 1800*6000 | 10.8 | 30 | 6200*3400*3500 |

| 3YK1860 | 0-300 | 0-200 | 1800*6000 | 10.8 | 22 | 6200*3400*4100 |

| 2YK2460 | 0-200 | 0-300 | 2400*6000 | 14.4 | 15*2 | 6200*4100*3800 |

| 3YK2460 | 0-300 | 0-300 | 2400*6000 | 14.4 | 22*2 | 6200*4100*4400 |

| 3YK3072 | 0-300 | 0-300 | 3000*7200 | 21.6 | 30*2 | 7400*4700*4700 |

| 3YK3672 | 0-300 | 0-350 | 3600*7200 | 25.92 | 55*2 | 7400*5400*4700 |

WhatsApp:8618037111663

WhatsApp:8618037111663